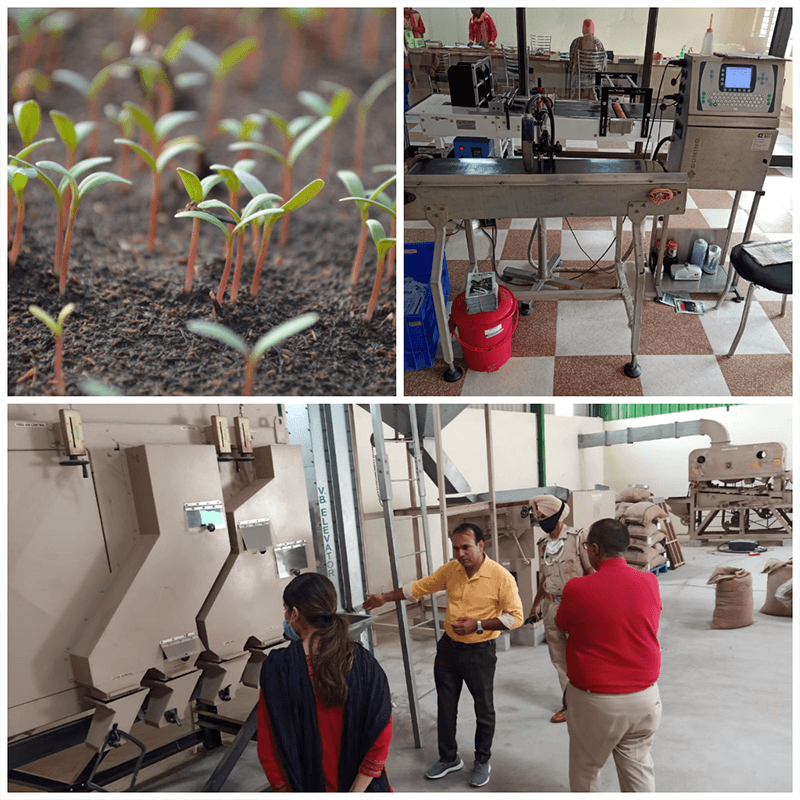

Initially, the seeds undergo a rigorous battery of quality tests, including assessments of physical purity, germination rates, viability, and Grow Out Tests, which simulate field conditions to verify performance. Only after achieving satisfactory results do the seeds proceed to cleaning, grading, treatment, and packing, where each step is carried out with precision to maintain integrity. Our packaging not only enhances shelf life but also provides crucial information to our customers regarding seed variety and optimal planting conditions.

The final products are then stored in our well-maintained warehouse and automated cold storage to preserve their quality, with temperature and humidity levels closely monitored to prevent any degradation. This commitment to excellence is further supported by our team of qualified personnel, who are continually trained in the latest techniques and technologies in seed processing. We also conduct regular audits and inspections to ensure compliance with both national and international quality standards, reinforcing our dedication to producing seeds that not only meet but exceed expectations in agricultural performance.